Good grief! Is that the time already? This post is way overdue. I’m guessing I might have applied the rule of thumb from my previous post maybe 5 – 10 times during the last month or so. What about you? I hope you get as much value from it as I have over the last 30 years.

Towards the end of that post, I suggested the answer this time around would be 150, but I gave no further clues about what the question would be. The title of this post should hint it has something to do with welds. I’ll leave it to others to offer guidance about making welds stick to steel; this post is about making weld strengths stick in your head. And all you have to remember is 150!

Still not much help without a few more clues is it? The next clue is “millimetres”. Hmmm, 150mm? In most welding contexts, that would make sense as a length; it’s unlikely to be the throat thickness. Weld length and weld strength are of course related, but how is 150mm likely to be helpful when so many different weld sizes are possible; 6mm fillets, 8mm fillets, 10mm, 12mm, 16, 20…..? Here it comes…

A 150mm long fillet weld carries its leg length in tonnes. That is, a 6mm fillet weld of length 150mm will carry 6 tonnes. A 150mm long 16mm fillet weld will carry 16 tonnes. A 38.1mm fillet weld will carry 38.1 tonnes per 150mm of length. Et cetera. I’ve adopted a dopey number like 38.1mm to help strengthen the demonstration, but is it really that dopey? Quick! How long must a 1½ inch fillet weld be to carry about 38 tonnes? Hint, 1½ inches = 38.1mm (we shouldn’t forget that some nations still use the imperial system).

Any rule of thumb can be dangerous without an appreciation of the caveats. This rule applies to equal leg fillet welds loaded in a single direction only. For loading in multiple directions, an accurate rule of thumb becomes almost as complex as a detailed stress analysis, but the 150mm rule offers a useful design starting point and a quick reality check. Designing for fatigue prone applications is another matter entirely (that post is coming).

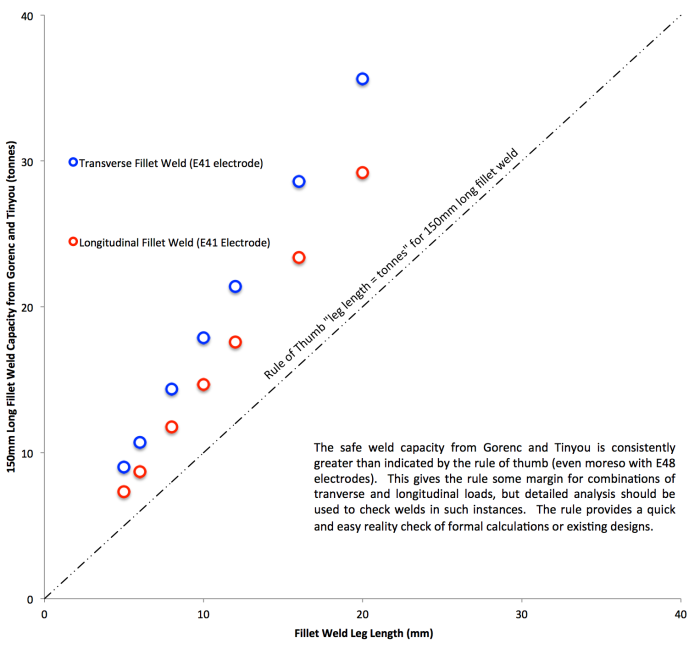

A graph comparing the rule of thumb and safe weld capacities extracted from the “Steel Designers Handbook” (Gorenc and Tinyou) is presented below. The rule is arguably conservative; 100mm would offer a tighter correlation. However, on reciting my rule to a more senior colleague a few decades back, he said, “Hmmm, I’d always assumed a ¼ inch fillet carries a ton per inch”. After we’d both gazed momentarily at that point in the top left corner of the room where it seems all answers to mental arithmetic lurk, we simultaneously announced “same thing near enough!” I’ve stuck with 150 ever since. I hope it helps welds stick with you too.

Next time will be a ‘lightweight calculation’ (yes, that’s a clue) before another rule of thumb combining well with today’s and the first. Until then, please don’t hesitate to offer any comments and corrections, or to ask any questions, or to subscribe and receive notifications about future posts.